Summary

The strong globaldemandforpropylenealongwiththeshortagesupplyfrommodernsteamcrackers provides a significant incentive for refiners to maximise propylene production from FCC units. To respond to this need, most FCC operators currently apply high activity ZSM-5 additives as the most cost-effective way to boost the propylene yield. In this paper, the authors discussed several key aspects for innovative design of high activity ZSM-5 additives, i.e. increased contents of ZSM-5 crystals, stabilisation of ZSM-5 framework by phosphorus treatment and optimisation of porous matrix. To illustrate these points, prominent examples in the development of new generations of high activity ZSM-5 additives from the world leading catalyst manufacturers were given. With the new high activity ZSM-5 additives, the desired propylene yield could be obtained with less ZSM-5 usage requirements. This translated in reduced dilution impacts and additive costs; thus enabling FCC operators to produce more propylene to meet the growing propylene demand.

Key words: ZSM-5 additives, FCC, propylene, light olefins, shale gas.

1. Introduction

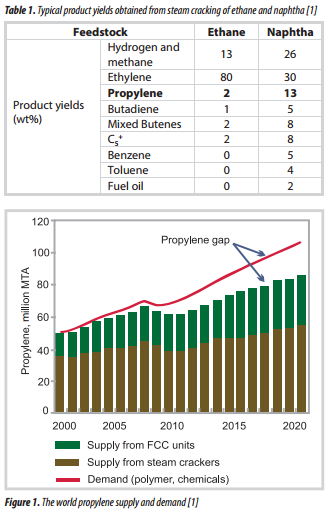

Propylene is an important raw material for producing many valuable products including polypropylene, acrylonitrile, propylene glycols, cumene, butyraldehyde and acrolein. Major sources of propylene supply are from steam crackers (ca. 60%) and fluid catalytic cracking (FCC) units (ca. 30%). The remainder is produced on purpose via propane dehydrogenation or metathesis (ca. 10%) [1, 2]. Due to the shale gas revolution, however, the feedstock for steam crackers is changing with less naphtha from crude oil and more ethane from natural gas, which decreases the propylene yield from steam crackers (Table 1). This opens an opportunity for FCC units around the world to enhance propylene production to keep up the growing demand for propylene (Figure 1).

In light of this, FCC operators have the following options to consider: (i) increase riser temperature, (ii) increase conversion, (iii) change feedstock composition and (iv) use ZSM-5 based additives [2]. Increasing the reactor temperature will enhance LPG and thereby the propylene yield. But it also produces more undesired products, i.e. dry gas and coke. More propylene can be obtained by increasing conversion. For every 1wt% gain in conversion, about 0.3wt% additional yield in propylene can be obtained. However, this option is limited because the increased conversion requires more coke burning. The feed composition has prominent influences on the product distribution of FCC units. A heavier residue type feed will give rise to a drop in the propylene yield as it has a high concentration of naphthenic molecules which have a strong tendency to act as hydrogen donors and to saturate olefin precursors. But the changing feedstock is not a practical solution since it depends on available crude oil sources. The use of ZSM-5 additives perhaps represents the most cost-effective way to raise the propylene yield from FCC units. Typically, only few weight percent of ZSM-5 additives in the inventory can greatly improve the propylene yield. In fact, most of FCC operators currently rely on ZSM-5 additives to achieve a significant boost in the propylene yield when market conditions demand such an action. In the present paper, the authors discuss several key aspects in the design of high activity ZSM-5 additives for maximum propylene production in FCC units along with excellent examples from the world leading FCC catalyst manufacturers including Grace Davison, BASF and JGC C&C.

2. Chemistry of propylene production by ZSM-5 additives

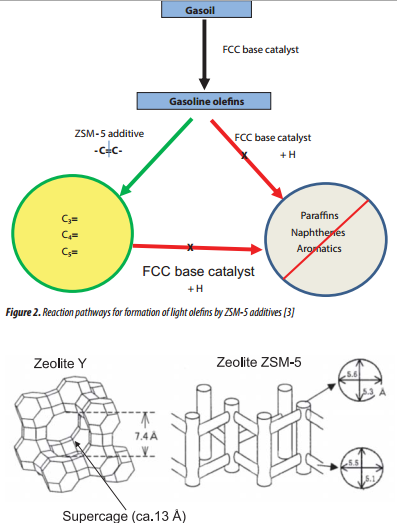

Addition of ZSM-5 additives to FCC units resulted in an increase in the gasoline octane rating, a decrease in gasoline and an increase in C3-C4 gas products, particularly propylene [3 - 6]. These results can be explained by the fact that ZSM-5 is shape selective zeolite which mainly cracks gasoline range olefins (typically C6-C9 hydrocarbons) into C3-C4 olefins. A simplified diagram of main reaction pathways for formation of light olefins upon addition of ZSM-5 additives is shown in Figure 2. Gasoline-range olefins are initially formed by conversion of FCC feedstocks (residues, gas oil, etc.) over the faujasite (Y) FCC base catalyst. Without ZSM-5 additives, these olefins tend to undergo hydrogen transfer reactions to make paraffin and aromatics since the faujasite base catalyst has strong ability to promote these bimolecular reactions [4].

When the ZSM-5 additive is injected, these gasoline olefins will be selectively converted into light olefins. The chemistry of ZSM-5 originates from its unique shape selectivity. The relatively small and tunnel- shaped pores of ZSM-5 (< 0.56nm) allow only linear compounds in the gasoline fraction to enter. Furthermore, the limited room in the pore system of ZSM-5 compared to the supercages (approx. 1.3nm diameter) in zeolite Y of the base catalyst implies that it is much more difficult to accommodate larger bimolecular transition states (Figure 3). Consequently, the secondary cracking reactions of gasoline olefins over ZSM-5 produce predominant C3-C4 olefins [3 - 6]. An accepted rule of thumb states that ZSM-5 additives should yield an LPG fraction with 50 - 60wt% propylene, 20 - 40wt% butene and 10 - 20wt% iso-butane. Hence, the increased C3-C4 olefins and decreased gasoline yields can be rationalised through these secondary reactions. On the other hand, it should be noted that gasoline paraffins have low octane ratings and thus their reduced concentration in gasoline induces an improved gasoline octane number.

To maximise propylene production, in principle, gasoline olefins generated by the base catalyst should be effectively converted over ZSM-5 additives to light olefins. This could be realised by using high ZSM-5 additive loadings, i.e. 15 - 30wt%. However, as the ZSM- 5 injection rate increases, the FCC base catalyst activity is diluted because the ZSM-5 additive does not exhibit cracking activity toward FCC feedstock [4, 5]. To address the need to use less ZSM-5 additives for maximum propylene production, catalyst manufacturers have focused on innovative design of ZSM-5 additives with high activity which allows FCC operators to lower ZSM- 5 additive loadings and still achieve the desired yield of propylene. Furthermore, to make ZSM-5 additives even more effective, a base catalyst with controlled hydrogen transfer reactions should be used since these secondary reactions consume olefin precursors to form undesired products (Figure 2). However, the development of FCC base catalysts with controlled hydrogen transfer reactions is not a subject of this paper and will not be introduced here. In the next section, several key points, i.e., using high content of ZSM-5, stabilisation of ZSM-5 by phosphorous treatment and optimisation of porous matrix for the design of high activity ZSM-5 additives for maximum propylene yield will be discussed in detail.

3. Design of high activity ZSM-5 additives for maxi- mum propylene production

In order to improve the activity of ZSM-5 additives, the following major aspects have been considered: (i) increase ZSM-5 content, (ii) stabilise ZSM-5 with new phosphorous treatment technology and (iii) optimise the porous system of matrix [1 - 8].

The formulation of ZSM-5 additives with high content ZSM-5 crystals has been proven as an efficient approach to obtain high activity ZSM-5 additives. But the technical challenge is that the physical properties of the additive (apparent bulk density, attrition resistance) deteriorate at high ZSM-5 contents [5]. Nevertheless, catalyst manufacturers have made it possible to keep these properties by using suitable catalyst preparation technology. Grace Davison first developed successfully a high activity ZSM-5 additive with a high ZSM-5 content namely “OlefinMax”. This additive contained ca. 25wt% ZSM-5 crystals which at the time was the maximum allowable under license [7]. OlefinMax soon established itself as the benchmark for high-activity ZSM-5 additives and is still the most widely used ZSM-5 additive, accounting for nearly half of all ZSM-5 uses. Recently, Grace Davison has introduced a new high activity ZSM- 5 additive called “OlefinsUltra” by optimising the matrix system. The intrinsic activity of OlefinsUltra is even higher than that of OlefinMax. By using this additive, FCC operators are able to reduce by about half the amount of ZSM-5 additive injected and still get the desired yield of propylene. This means that they can lower fresh catalyst consumption by more than 10%. Up to date, OlefinsUltra has been used successfully in more than 17 refineries around the world, including Dung Quat refinery in Vietnam.

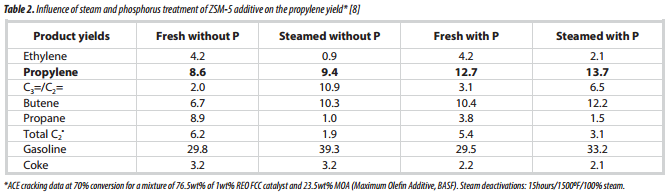

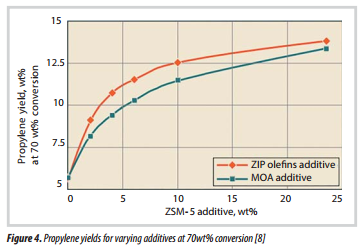

Phosphorus treatment is extensively used in the fabrication of ZSM-5 additives to slow down the dealumination of the ZSM-5 framework [6 - 8]. This stabilisation retains more active acid sites and thus higher activity for treated ZSM-5 additives. In this connection, BASF has recently developed a new generation of high activity ZSM-5 additives, called “ZIP Olefins Additive”, based on multi-stage phosphorus treatment technology [8]. For this purpose, they have made intensive efforts on understanding the role of acid sites in enhancing the propylene yield. It was found that the phosphorus based acidity rather than ZSM-5 framework acidity plays a key role for the improved propylene yield upon steaming. Accordingly, steaming and subsequent phosphorus treatment should be employed to generate more phosphorus based acidity and the consequent propylene yield (Table 2).

By utilising the new phosphorus treatment technology, ZIP Olefins Additive is able to produce more propylene at the same ZSM-5 loading and crystal content as MOA (Maximum olefin additive, a standard additive product of BASF). Since product selectivity for ZSM-5 additives is primarily linked to the shape of the zeolite itself, there is no change in selectivity for ZIP Olefins Additive with respect to other ZSM-5 additives. However, because of ZIP’s higher activity, the desired light olefin yield is obtained using less ZSM-5 additive (Figure 4).

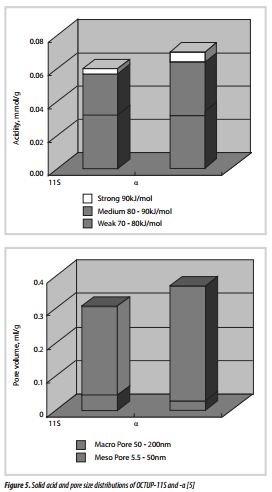

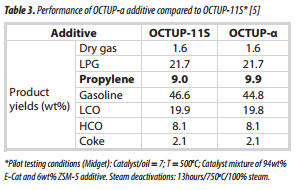

For the pore design of ZSM-5 additive, it is of importance to properly balance micro-, meso- and macroporosity within the additive. Through the hierarchical porous system of the matrix, gasoline olefins (reactants) easily diffuse to the active site of ZSM-5 and thereby give an increased performance. Based on this concept and employing high content ZSM-5 formulation technology, JGC C&C has developed an advanced ZSM-5 additive named “OCTUP-α” [5]. The catalytic data in Table 3 shows that OCTUP-α is superior to OCTUP-11S, a standard additive from JGC C&C due to the increase in pore volume and the increase in acidity from a greater amount of ZSM-5 crystals (Figure 5).

4. Conclusions

Maximisation of propylene production has become a focus of most refineries because of the increasing global demand for propylene and the shortage supply from modern steam crackers, which now produce relatively less propylene. To achieve this, most refiners rely on the use of ZSM- 5 additives. The paper discusses three key points for innovative design of high activity ZSM-5 additives, including formulation with high ZSM-5 contents, stabilisation of ZSM-5 crystals with new phosphorus treatment technology and optimisation of porous matrix. By utilising these techniques, catalyst manufacturers have successfully developed new generations of high activity ZSM-5 additives which allow the use of less ZSM-5 additives than the traditional ZSM-5 additives while still achieving the desired propylene yield. This opens the way for FCC operators to increase propylene production to fill the gap between propylene supply and demand.

Acknowledgments

This work is part of the state-level project entitled “Development of technical ZSM-5 additives using Vietnamese resources for enhancing the propylene yield from the RFCC Unit of Dung Quat refinery” funded by the Ministry of Science and Technology of Vietnam under the National Science and Technology Research Programme (Grant No. KC.02.03/16-20).

References

1. Aaron Akah, Musaed Al-Ghrami. Maximizing propylene production via FCC technology. Applied Petrochemical Research. 2015; 5(4): p. 377 - 392.

2. M.Lesemann, W.C.Cheng, James R.D.Nee, Sergio Sobrinos, Gordon H.McElhiney. Increasing FCC propylene. Digital Refining. 2006.

3. J.Knight, R.Mehlberg. Maximize propylene from your FCC unit. Hydrocarbon Processing. September 2011: p. 91 - 95.

4. J.S.Buchanan. The chemistry of olefins production by ZSM-5 addition to catalytic cracking units. Catalysis Today. 2000; 55(3): p. 207 - 212.

5. Rei Hamada, Mitsunori Watabe. More propylene in FCC units. JGC Catalysts and Chemicals Ltd. 2007.

6. E.T.C.Vogt, B.M.Weckhuysen. Fluid catalytic cracking: recent developments on the grand old lady of zeolite catalysis. Chemical Society Reviews. 2015; 44: p. 7342 - 7370.

7. J.R.D.Nee, M.Lesemann. Propylene production in the FCC unit: An opportunity to increase refinery profitability. Davison Catalagram. 2004; 94: p. 3 - 10.

8. Carl Keeley, Vasileios Komvokis, Modesto Miranda, David Harris, Jason Smith. ZSM-5 additive maximises propylene. Digital Refining. 2015.