Bach Ho oil field (Photo: Petrovietnam)

A mission throughout 60 years of construction and growth

Petrovietnam’s scientific and technological research, development, and application is an overarching mission assigned by the Party and State during Petrovietnam’s construction and development.

The Politburo’s 2015 Resolutions on “Development strategy of Vietnam’s petroleum sector until 2025, vision to 2035” and 2020 Resolution on “Development strategy of Vietnam’s energy development until 2030, vision to 2045” highlight that Petrovietnam has to apply science and technology for exploring and increasing petroleum reserves and oil, gas, electronic, fertilizer, and new energy production (oil shale, gas hydrates, and hydrogen gas) to ensure national energy security.

The Development Strategy of Vietnam’s Petroleum Sector stresses the need to build a strong scientific and technological capability with breakthrough measures. It’s the motivation and foundation for the Group to speed up its development and sustainable development.

Over the past 60 years, Petrovietnam has continuously improved its scientific and technological research and optimized technological efficiency to reach the level of regional and international oil and gas companies. Hundreds of honorary awards were given to scientific and technological findings, including 5 Ho Chi Minh and State awards and many VIFOTECH awards.

This year Petrovietnam’s 6 outstanding projects has been nominated by the Ministry of Industry and Trade for the Ho Chi Minh and State awards.

Achievements of those with limited resources

The solution to soon transport associated gas from offshore fields to shore has generated power worth millions of USD for Vietnam’s Southeastern region; the TBM-02 synthetic carota measurement station system made a profit of about 115 million USD; and Technological solutions to optimize the production of the Dung Quat oil refinery generated a profit of 180 million USD. Worthy of note, all scientific and technological research and application projects at Petrovietnam began with limited resources.

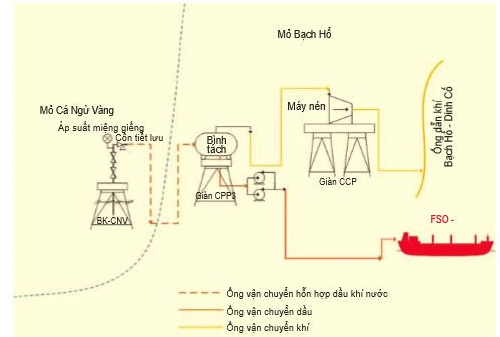

Diagram of collecting and transporting associated gas from WHP-CNV Ca Ngu Vang field to Bach Ho field (Photo: Petrovietnam)

Petrovietnam’s success is linked with the project on research and application of technological solutions to collecting, processing and using associated gas at Vietsovpetro fields and neighboring fields, which started in the early 1990s. When the Vietsovpetro joint venture began exploiting oil at Bach Ho, the technology at that time could only allow the company to exploit oil and the associated gas had to be burned. The fact that Vietnam suffered severe shortage of electricity for economic development prompted Vietsovpetro's officers and engineers to collect, transport, process and bring the associated gas to shore for power generation and nitrogen fertilizer production. In 1995 after oil extraction, with breakthrough scientific and technological solutions but poor infrastructure, Vietsovpetro again pioneered to bring associated gas from Bach Ho field to shore, creating a giant leap forward for Vietnam's oil and gas industry and laying a foundation for the development of modern gas industry.

The TBM-02 synthetic carota measurement station system marks another scientific and technological milestone of Petrovietnam. Since the early 1990s, when Vietnam started to export its first tons of oil to earn hard currencies, Vietsovpetro staff realized that they had to learn oil and gas exploration and exploitation of the Soviet Union to bridge the technological gap between Vietsovpetro and the western countries.

Nguyen Xuan Quang, Director of the Vietsovpetro Drilling and Well Repair Factory, said that in the 1990s Vietnam’s petroleum sector were totally dependent on the Soviet Union’s technology from equipment to training. Vietsovpetro’s geophysical well logging technology as well as other tools were manual which made its quality unable to compete with international companies because it took several months to come up with a conclusion, while developed countries doing the service in Vietnam finished it in a week.

In order to stay in the game, the staff of Vietsovpetro Geophysical Well Logging Factory tried to study and innovate technology. In these years, Vietsovpetro experts and engineers collected equipment, which was seen as “unrepairable and unbuyable”, to study, analyze, and integrate their best functions to produce a synthetic carota measurement station worth only 5,000 USD, less than 10% the price of a similarly imported equipment. The portable equipment is very simple and easy to use for petroleum people in general and geophysicists in particular.

Compared to a Russian measurement station and corresponding equipment weighing up to hundreds of kg, the multi-function measurement station developed by Vietsovpetro weighs less than 10kg and is as small as a laptop. It can examine geographical documents and measure cracked rocks containing oil. It’s a small device with the most functions in the world compared to products of the world’s top manufacturers like Haliburton of the US or Huangding of China.

In 2009, Bien Dong Petroleum Operating Company, BIENDONG POC, was assigned by the government to study and carry out major projects. The central processing platform (PQP-HT) with a living platform was a superstructure weighing 12,500 tons and the base weighing 11,500 tons. International consultants said it was an impossible mission. PTSC Mechanical and Construction Company (PTSC&MC), which was assigned this task, seemed to be deadlocked because they had to start the job from nothing. They overcame various difficulties to finish the project in two years. At present, with the successful construction and operation of the super long and super heavy drilling platform, PTSC&MC has become Vietnam’s sole EPCI contractor (Engineering, Procurement, Construction, and Installation) in the international market with contracts worth over 600 million USD with investors from India, Japan, Ghana, and Qatar.

Dung Quat Oil Refinery (Photo: Petrovietnam)

When the Dung Quat Oil Refinery, Vietnam’s first oil refinery, started operation, its staff and engineers were all new to the job so incidents were unavoidable. At the beginning, product’s quality was unstable. Petrovietnam defined that improving operation efficiency and quality was a regular, long-term task. Innovation and renovation was carried out during the production. Despite the poor performance in the first years, the Group believed in the young staff and engineers who were trying their best to improve quality and efficiency. Over the last 12 years, more than 30 solutions and initiatives have been applied which have increased designed productivity of factories and ensured the best product quality.

Driving force and foundation for sustainable development

Science and technology have been applied in all production and business activities of the Group, particularly in its specialized areas. The results of research projects are important for the Group to work out long-term development strategies and help other sectors make decisions for national development. Fundamental investigation study has guided and paved the way for in-depth research to explore non-conventional oil and gas resources such as coal gas, clay gas, and hydrate gas.

Petrovietnam has encouraged scientific and technological research by organizing innovative contests, honoring initiatives and innovations, and holding national and international scientific and technological conferences and seminars, and forums to exchange ideas, information, experience, and solutions.

Technology is foundation of industry. Strengthening technological management capability is vital for a technical, economic group like Petrovietnam.

Research and development in the petroleum sector has economically benefited the nation and contributed to the petroleum science of Vietnam and the world. It’s an evidence of creativity of Vietnamese people in general and petroleum personnel, who make the impossible possible.

To mark the 8th Vietnam Science and Technology Day on May 18, Hoang Quoc Vuong, Secretary of the Party Committee and Chairman of the Members’ Council of Petrovietnam, sent a letter to former and current managers, researchers, and those involved in scientific and technological research at Petrovietnam. The letter said that in 2021 the Group begins research plan until 2025, which will be the foundation to develop signature products and services to compete in the domestic and international market.

The Chairman urged all affiliates to mobilize resources to implement key scientific and technological plans. He called on managers and researchers to exert greater efforts, apply achievements of the 4th Industrial Revolution into the Group’s production and business, and create breakthrough solutions, contributing to stable, sustainable development of the Vietnam Oil and Gas Group.

vovworld.vn